Tank inspection ensures the safety and integrity of aboveground storage tanks by preventing accidental leaks and avoiding costly decontamination, while providing critical data so lifetime and repair predictions can be made. There are continued advances in new non-destructive testing (NDT) technologies that improve detection of defects and accuracy of sizing.

Tank Integrity Inspection Solutions BrochureDetails

Any supply distribution system has the important goal of meeting the demands of consumers in a timely and cost-effective manner. The same is true for the petrochemical industry. This sector typically employs aboveground storage tanks (ASTs) for storing petroleum product to balance supply and demand. This highlights the importance of the availability and reliability of these critical assets.

Tank inspection ensures the safety and integrity of tanks by preventing accidental leaks and avoiding costly decontamination, while providing critical data so lifetime and repair predictions can be made. Tank inspectors provide trend info on current asset condition and recommended actions for owners and operators to secure a statutory operating license; they can potentially negotiate lower insurance based on validation that plants are in good condition.

Storage tank integrity assessments are not limited to in-service tanks. Tanks may be assessed during construction in order to collect baseline data for audit purposes. After the manufacturing process, there is a requirement to validate new tank construction welds among other components for fitness-for-service and regulatory compliance. Furthermore, decommissioned tanks may be brought back online to accommodate a demand for additional storage. A comprehensive inspection is required before returning a retired storage facility to use; experienced professionals understand specific recommissioning tank requirements and acknowledge the need for advanced tools to assess the condition of storage tanks to make critical decisions at every stage of a tank’s lifecycle.

.jpeg?preset=details-img-fb)

Despite their apparent simplicity, many tank components must be inspected. Tank inspection includes assessing the infrastructure of fixed or floating roofs including domes and seals, shell aperture, settlement analysis and strapping. Both internal and external corrosion usually take the form of isolated attacks governed by roof geometries, construction methods, plate flatness, and coating conditions. Critical areas involve bottom plates, shell plates, annular rings, roof plates and all welding joints. While it’s assumed that leakage will occur before a failure, highlighting thin areas of a tank shell, this is not always the case; there may be catastrophic failure without any prior leakage. Monitoring the tank exterior for general metal loss in various areas provides a useful integrity assessment, but the extent of inspection necessary depends on the product stored, tank age, and historical inspection results.

There are continued advances in new non-destructive testing (NDT) technologies that improve detection of defects and accuracy of sizing. All systems have some limitations and knowing which tool is best for each measurement is important. NDT techniques can be complimentary, and in some cases, they may need to be combined to give the best result. The actual condition of the tank being inspected will also influence measurement accuracy, and this should be considered.

Learn more

Tank Floors

A common failure mechanism is leakage through the floor, damaging the tank foundation which leads to instability possibly resulting in catastrophic failure. The most common technology used to inspect bottom plates for corrosion is magnetic flux leakage (MFL) because of its sensitivity to volumetric variations. MFL uses a strong magnet to induce a magnetic field in the bottom plate. When it encounters corrosion of a certain size, the magnetic field “leaks”. The more important the proportional volumetric rate, the greater the leakage. Leakage is detected by a combination of several types of sensors, but MFL technology is incapable of detecting whether defects are on the top or bottom side of plates. For this reason, we combine MFL with surface topology air-gap reluctance sensors (STARS). This enables completely mapping storage tank floors and discrimination between top and bottom defects. The FloormapX is the most advanced magnetic flux leakage floor scanner on the market, complemented by Handscan, an inspection tool ideal for storage tanks 10 meters (33 feet) or less in diameter, petal floor plates, and in-situ heating coils. Floormap vastly reduces the time it takes to inspect tank floors while producing detailed and accurate reports, enabling engineers to determine optimum maintenance strategies.

Assessing the integrity of annular rings can be performed from the exterior of the tank, so the tank does not need to be taken out of service. The Eddyfi Lyft® PEC solution offers an excellent way to inspect for wall loss in atmospheric storage tank annular rings without taking them offline. The tank floor probe is specifically designed for this type of inspection. Because it is super thin, the probe can slide up to 400 millimeters (16 in) under a tank floor’s edge, enabling it to assess the remaining wall thickness of this critical region exposed to corrosion.

The Alternating Current Field Measurement (ACFM®) technique was specifically developed to detect and size surface-breaking defects at welds and can work through several millimeters of non-conductive coating. Recognized by API, ACFM is a natural choice for inspecting storage tank welds to supplement corrosion mapping.

ACFM is a cost-efficient and reliable method for inspecting storage tank welds, capable of detecting and sizing cracks through coatings without the need for surface preparation. It offers undeniable cost savings compared to MPI by eliminating the labor-intensive process of coating removal and recoating. ACFM inspections are typically six times less expensive than MPI while providing reliable results and comprehensive data records for asset owners. To further enhance the cost and productivity advantages of ACFM, advanced array probes are employed for various weld types, including fillet welds, butt welds, and lap joints. The ACFM fillet weld array probe features a rugged monoblock design and incorporates a clever crack length estimation method, making it ideal for targeted inspection conditions. When assessing floor and shell joints, including lap joints, the high-speed ACFM array probe offers additional cost reductions compared to MPI. The overall inspection process becomes up to five times faster than with previous ACFM probes. The array probe scans areas up to 90 millimeters (3.5 inches) wide, utilizing twin-field technology for biaxial crack detection and sizing.

Tank Shells

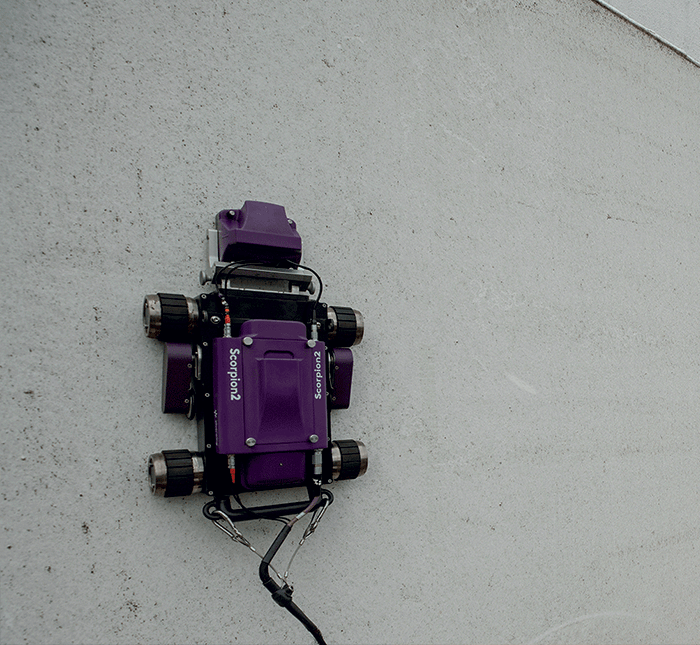

The most common method used to assess shell wall thickness is with a remote access ultrasonic testing (UT) crawler, typically designed to perform cost-effective UT thickness measurements on aboveground ferromagnetic structures without the need for scaffolding or rope access. UT crawlers can operate automatically or manually. They perform line scans on the tank shell surface or scan specific areas including the roof (involving more sophisticated XY scanners). In most cases, tank shells are divided into 8, 16 or more equal sections as specified by the inspection regulation. B-scan UT data is recorded for each section from bottom to top, showing the condition along each course. The speed of the UT crawler and the data acquisition rate play a great role in the efficiency of tank wall surface inspections. Some crawlers can travel and inspect up to 180 millimeters per second (7 inches per second) with a dry-coupled wheel probe, which eliminates the need for the complex water supply system usually necessary in UT inspections. Silverwing Scorpion 2 is the ideal UT crawler for inspecting tank shells, as it was designed specifically to answer the needs of the industry.

When greater precision and more detailed mapping is required, automated corrosion mapping using phased array UT (PAUT) is the ideal option because it allows inspecting large areas rapidly without compromising data quality. Phased Array probes have a wide electronic footprint and with a one-millimeter (0.04 inch) resolution across the beam width, the required scanning coverage is achieved in significantly less time. The ability to collect high resolution data at increased scanning speeds improves the probability of detection, enhances imaging and improves defect characterization. The automated PA solution – leveraging not only PAUT but also Total Focusing Method (TFM) – is a unique tool for automated corrosion mapping of storage tank shells.

Tank Roofs

Just like the other components of aboveground atmospheric storage tanks, roof plates must be inspected for corrosion and deformation, and cracking in welding joints. MFL and remote UT crawlers used on shell plates can also be used on the roof. Eddy Current Array (ECA) and UT can be used to test all weld joints.

Assessing Inside Condition

While some inspections require shutting down the asset and pre-cleaning, not all do. It is recommended to regularly conduct visual inspection on open tanks, ideally identifying problems to perform repairs before a significant leak occurs. Maintaining this critical asset is key. Therefore, Remote Visual Inspection (RVI) with robotic inspection crawlers like the quickly deployed VersaTrax™ provides data in real time without the need for expensive scaffolding or rope access.

Eddyfi Technologies’ range of inspection equipment and reporting tools play an important role in assessing the condition of storage tanks and recording data for trending analysis. With current records of inspection for compliance, operators can secure and maintain their operating license and even negotiate lower insurance based on positive condition assessment results. Owners and operators can minimize out-of-service periods to ensure the maximum productivity of tanks and ultimately supply chain integrity.

Ask an Expert![]()