The Swift™ and Scorpion® 2 dry-coupled remote-access ultrasonic crawler bring major efficiency and data improvements to tank shell inspections and other structures such as vessels and offshore installations. API 650/653 compliant, this powerful duo from Silverwing is the perfect solution for in-service inspection of your assets.

Details

Benefits

- High-speed, complete a 10-meter scan in under a minute

- 3 component system for faster deployment

- Floating and tracking UT gates for repeatable and reliable results

- Higher Probability of Detection (POD) compared to spot reading

- Dry coupled rolling probe for quick and easy setup

- Remote access up to 50 m (164 ft)

Applications

- Storage tank shell

- Storage tank roof

- Vessels

- Offshore installations

Want to see Scorpion 2 in action? Book a demo!

Inspection Standards

Traditional tank shell or roof inspection techniques such as spot readings with a manual UT thickness gauge can prove misleading because of their low Probability of Detection (PoD). This may result in incomplete corrosion rate and Risk-Based Inspection (RBI) calculations. Silverwing Scorpion2 records thickness measurements along a vertical line, even in the heat-affected zone (HAZ) or 25 mm (1 in) from the plate weld, as recommended by EEMUA, yielding higher PoD for a more accurate corrosion assessment.

EEMUA also states that walking on tank roofs can be hazardous. The condition and thickness of roof plates should be confirmed before access is permitted. Silverwing Scorpion2 can remotely perform this task, reducing the need for roof access.

Ultrasonic Performance

Scorpion 2 is equipped with the best ultrasonic electronics and software the industry has to offer. With its advanced filtering, the system can inspect materials 4.7–100 mm (0.19–3.94 in) faster and more accurately than other solutions on the market. The Swift software enables unique UT gate processing (such as floating and tracking gates), ensuring correct wall thickness measurements under most circumstances.

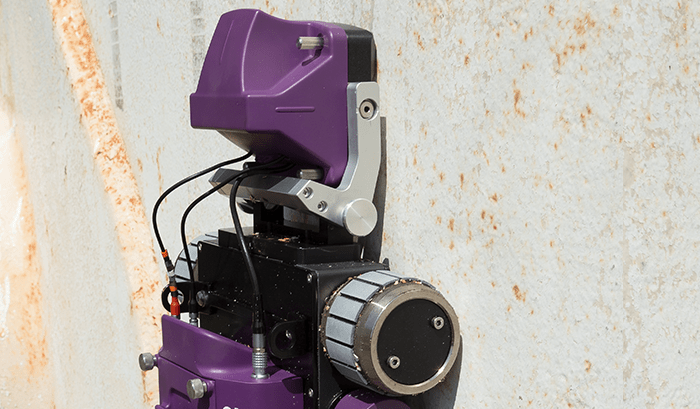

Probe Design

The unique, Silverwing dry-coupled ultrasonic wheel probe eliminates the need for couplant or a constant water supply. The twin-crystal ultrasonic trasducer combined with a unique rolling probe face allows for a fast and easy setup.

Probe Carriage

It enables the solution to record thickness measurements in the critical Heat-Affected Zone (HAZ), 25 mm (1 in) from a weld cap. The four independent-power magnetic wheels and their treaded tires offer Scorpion2 the ability to easily move over 12.7 mm (0.5 in) bumps and an excellent grip under any condition.

Active Probe Lift and Balance

Unique to Scorpion 2, active probe lift raises the wheel probe when measurements are not being collected, extending the life of the probe’s tire. Active probe balance makes it easier and faster to set up the probe before inspections, increasing repeatability.

Battery Powered

Scorpion 2 comes with two lithium-ion battery packs for continuous on-site operation. It uses one battery mounted inside the crawler, removing the need for a separate power source, as well as reducing umbilical and overall system weight.

Swift U

With a large, 26.4 cm (10.4 in), non-reflective, multi-touch screen, Swift offers crystal-clear displays under most lighting conditions.

Swift is sealed and designed for IP65. Its magnesium alloy casing is tough, water and dust resistant. Combined with a 3 mm (0.12 in) strengthened glass, it’s the perfect instrument for harsh environmental conditions.

Swift uses two lithium-ion, hot-swappable batteries, making a full day’s work easy. Swift can also be used with an optional harness to make using it for more extended periods less strenuous. The adjustable stand, the top handle, and the four corner anchor points make Swift extremely practical on-site.

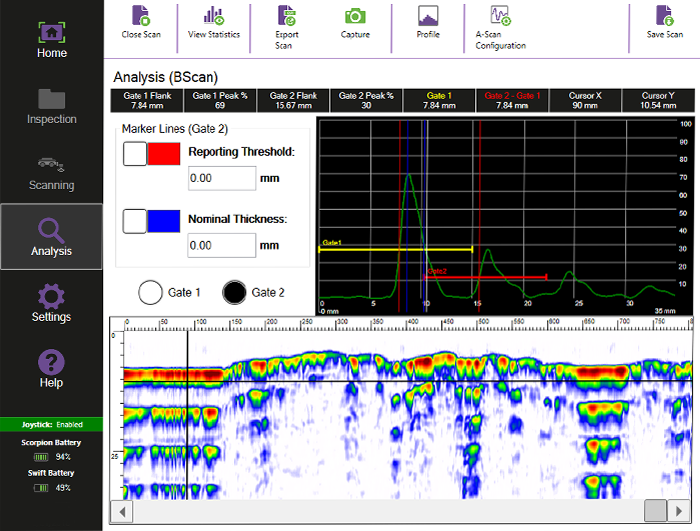

Swift GO Data Acquisition Software

Swift B-scan data acquisition software features several robust data capture, analysis, and reporting tools.

Users can review saved data at any time with active A-scan and B-scan displays. Placing the cursor over any part of the B-scan profile shows the A-scan trace for that specific section of the scan. Furthermore, you can display an adjustable reporting threshold indicator over the B-scan profile, helping identify reportable defects at a glance and enabling the rapidly analyzing of complete scans.

The full-amplitude B-scan mode helps characterize wall loss, which, in turn, makes detailed post-inspection analysis and accurate corrosion assessments possible.

Export options include CSV files, A-scan, and B-scan images, or as CMX files, which you can then import in CMAP inspection management software.

Exclusive Content

Increase the efficiency and data quality of your tank shell inspections

Watch the webinar to see the exceptional performance of the Swift and Scorpion 2 remote-access ultrasonic inspection solution, hosted by Edwin Van Der Leden, product manager. The webinar covers inspection setup, crawler controls, data collection, data analysis and a Q&A.

Scorpion2 Inspection Data Reporting with Excel

The instructional video explains the Scorpion2 and R-scan UT data reporting Marco. Video includes :

- Saving data in Excel format with 1 mm step

- Filtering data

- Merge and append data

- Template to summarize the data

- Generate report

Scorpion2 Inspection Data Example Report

Specifications

SWIFT

- 355 × 288 × 127 mm (14.0 × 11.3 × 5.0 in)

- With batteries: 6.6 kg (14.5 lb)

- Without batteries: 5.7 kg (12.5 lb)

- 13 L (791 in3)

- 100-240 VAC, 50-60 Hz

- Direct VAC or onboard batteries

- Li-ion, rechargeable, DOT compliant

- Typical life 6-8 hours

- 26.4 cm (10.4 in)

- Non-reflective (AR coating)

- Anti-fingerprint (oleophobic coating)

- 3 mm (0.12 in), strenghtened glass cover

- Optically bonded LCD and touchscreen

- SSD, 100 GB

- Gigabit Ethernet, Wi-Fi™, Bluetooth®, USB 2.0 (×3)

- Designed for IP65

- 0–40°C (32–104°F)

- 95%, non-condensing

SCORPION 2

- 494 × 294 × 130 mm (19.5 × 11.6 × 5.1 in)

- With batteries: 10.5 kg (23 lb)

- Without batteries: 10 kg (22 lb)

- 50 m (164 ft)

- 4.25 kg (9.4 lb)

- Onboard battery

- Li-ion, rechargeable, DOT compliant

- 4 hours (typical)

- 180 mm/s (7in/s)

- Active steering, four independent 12 V DC motor drive

- 4 × neodymium, iron, boron magnetic wheels

- 5 MHz twin element, dry-coupled

- 2.5 mm (0.1 in)

- Self-normalizing probe

- Designed for IP62

- 0–40°C (32–104°F)