Like any manufacturing process, casting is vulnerable to defects or undesired flaws in parts being made. Non-destructive testing (NDT) is a common method for inspecting castings without having to damage the product under assessment. NDT can help identify defects that adversely affect the material strength.

Details

Casting is a process where liquid materials are typically put in a mold to solidify, the resulting component removed and also called a casting. Like any manufacturing process, casting is vulnerable to defects or undesired flaws in parts being made. Non-destructive testing (NDT) is a common method for inspecting castings without having to damage the product under assessment. NDT can help identify defects that adversely affect the material strength.

Cracks

Cracks appear after a melt has solidified in the form of thin fissures on the casting surface.

Inclusions

Inclusions are nonmetallic elements in an otherwise solid metallic matrix.

Porosity

Gas porosity or blow holes are a series of pockets or voids in the metal.

Shrinkage

Shrinkage is the result of molten metal shrinking as it solidifies in the casting. This includes:

- Cavity shrinkage

- Dendritic shrinkage

- Filamentary shrinkage

- Sponge shrinkage

For the inspection of surface-breaking cracks in casting, eddy current array (ECA) can offer a fast solution depending on the part geometry. Eddyfi padded ECA probes, for example, can detect small cracks in castings. We can also design custom ECA probes for specific requirements. Probes work with Eddyfi Reddy®, the first portable instrument that unlocks surface inspection to a range of new applications. When it comes to surface detection of cracks, eddy current testing is optimal.

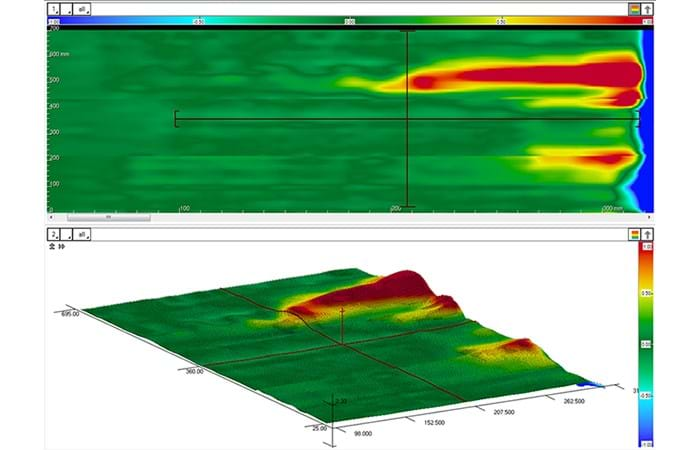

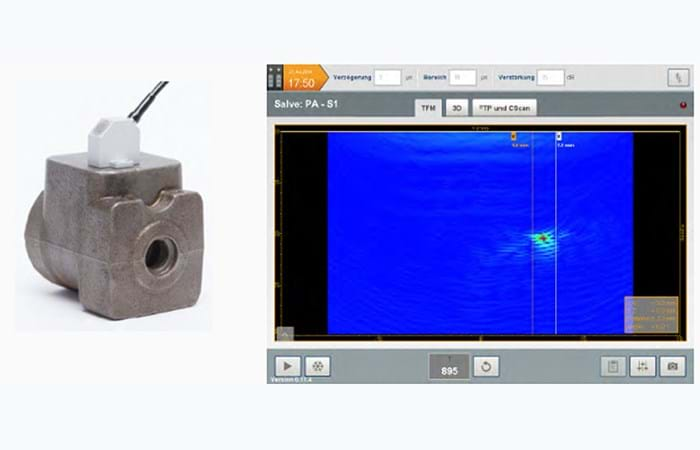

For casting volumetric inspection, ultrasonic testing offers a relevant solution. The M2M Gekko® is a phased array ultrasonic testing (PAUT) portable unit and was the first flaw detector offering at the same time conventional UT, standard PAUT, TOFD and real-time total focusing method (TFM). The imaging provided by the Gekko or M2M Mantis™ allows the observation of discontinuities with great accuracy. To identify casting defects, PAUT can be employed to monitor inclusions, porosity, and shrinkage through a streamlined software interface, Capture™.

The M2M Panther™ is designed for desktop and industrial applications, offering unparalleled performance in a compact unit. It comes with the speed required for industrial integrated PAUT solutions with the most complete set of Total Focusing Method (TFM) imaging techniques, making it the ultimate tool for casting defect detection. Recognized among the highest resolution UT techniques, TFM is standard on Panther with TFM pictures of 1.5+ million pixels in real time. It provides better flaw detection and easier defect characterization.

Eddyfi Technologies offers optimal NDT solutions for casting defect inspection applications, ensuring production efficiencies and effective quality control.